The SR – LWL – 2L/F2500 is a double Laser Device Welding Line for the production of Full Plate Solar Absorbers either in Grid or Serpentine form. The SR – LWL – 2L/F2500 in its Standard version comprises only the Main Welding Machine, where the operator unloads manually the ready product and puts manually in position the sheet-and-frame set to be welded.

Double Laser Device Welding Line

SR-LWL-2L/F2500

SR-LWL-2L/F2500

The SR – LWL – 2L/F2500 is a double Laser Device Welding Line for the production of Full Plate Solar Absorbers either in Grid or Serpentine form. The SR – LWL – 2L/F2500 in its Standard version comprises only the Main Welding Machine, where the operator unloads manually the ready product and puts manually in position the sheet-and-frame set to be welded.

Specifications

The Main unit comprises the following:

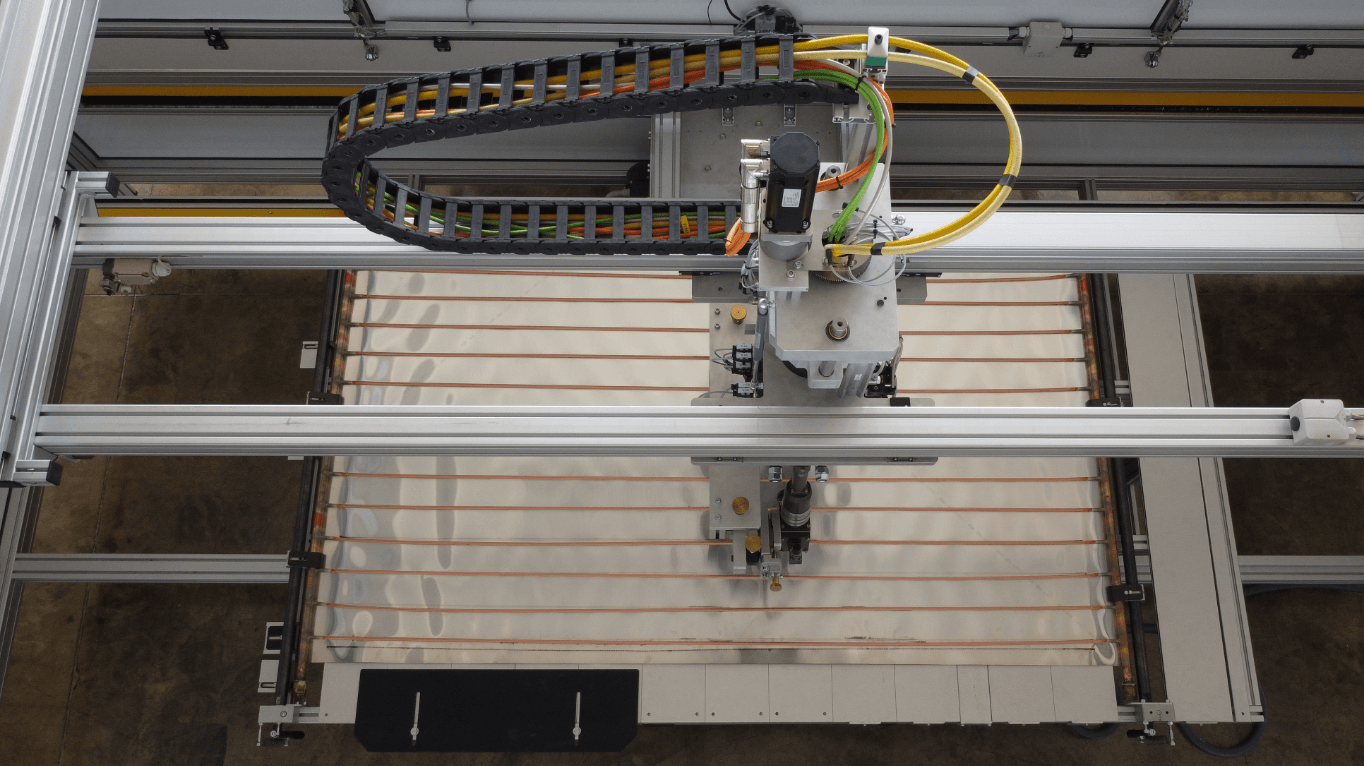

- Main Laser Welding Machine (SR – LWL – 2L/F2500)

- Welding head with 3-axis linear system (x & y axes servo motor driven – z pneumatically driven).

- Servo motor rotation of the welding head from 0 to 180o around the z-axis (horizontal plane).

- One off Welding table with manually adjustable positioning limits for the sheet and the frame to be welded as well as a manually operated clamping system.

- 2 TRUMPF Tru Pulse 556 Laser Device with 2 Laser light cables.

- Laser Class 1 Protection.

The main Machine can be outfitted with the following optional extras:

- Water Chiller, to cool the Laser Device. It is necessary only if adequate in-house cooling means do not exist. Required cooling capacity is 30 kW for both Laser Sources

Technical

characteristics

- Dimensions and welding parameter setting: Industrial Panel PC

- Control Managed by PC

- Repeatability Tolerance: ± 0,2mm (according to speed)

- Production Performance (L=2500 mm, 10 tubes): 20 Pcs/hour

- Max welding Speed: 10 m/min

- Voltage: 400 V/ 50 Hz

- Total Installed Power:65 KW

- Compressed air pressure: 6 bar

- Air Consumption: 50lt/min

- Machine weight: 500 kg

- Machine overall size: 6500x6500x1800 mm

Characteristics of the PC

- Program editor

- Diagnostic alarms

- Number of pieces counter

- Self-power shut-down at the program end with programmable time

- Easy settings

- Touch screen Monitor 19”

- Protections IP65

- PLC I/O.

- E-won Ethernet Router for internet access to the machine for production data downloading , production monitoring and error messages development.

Product Specifications:

- Solar Panel Width: 600 to 1265 mm

- Solar Panel Length: 600 to 2500 mm

- Riser tubes: Capability OD 8mm – 15mm

- Pitch: 40 mm min

- Wall thickness: 0,35 mm min

- Material: Semi-hard copper (280-320 N/mm2)

- Manifolds: OD18 - 28mm

- Wall thickness: 0,60 mm min

- Material Semi-hard copper: (280 - 320 N/mm2)

- Sheet material: Copper SF-Cu, OF-Cu, E-Cu R240 Aluminum Al 99,7

- Sheet thickness: Copper 0,12 έως 1,00 mm

*The number of riser tubes is limited only by the minimum riser tube pitch and the maximum absorber width.

- Performance-Standard version (2 m2 absorber):

Average welding time (Double Laser Device) 110 – 120 sec - Required Manpower:

Only one (1) person is required to operate, load and unload the machine.

Gallery